Services

Here is the list of all our services

Hydra-Spec Inc. offers water infrastructure inspection and maintenance services through OPA or P6B certified technicians and specialized computer tools.

Strong of our 20 years of experience, our growth is proof of the trust that our customers place in us, the commitment of our employees and the quality of our services. We carry out various mandates with cities and municipalities as well as with commercial and industrial clients on the entire territory of Quebec and Ontario.

Inspection of fire hydrants

• Assessment of the mechanical condition and hydraulic capacity of fire hydrants.

• Operational and sealing assessment.

• Inspection of isolation valves and their housing.

• Reading of static and dynamic pressures and calculation of actual flow and available flow with residual pressure at 20 psi.

• Systematic leak listening with acoustic amplifier.

• Reading of the height of the water table and the quality of drainage.

• In accordance with NFPA standards, CNPI and law 112 on fire safety.

• Experienced technicians certified by OPA or P68.

• Detailed computerized report including intervention priorities, thematic plans and register with intervention history.

• Free asset viewer with graphical interface.

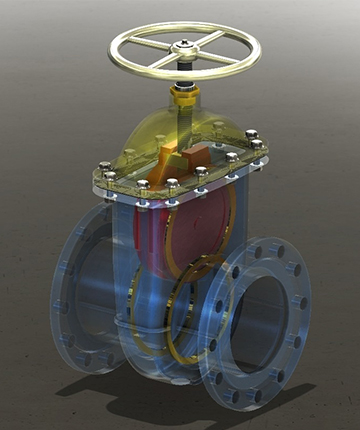

Inspection of main line valves

• Complete inspection and analysis of the mechanical condition andstructural condition assessment of boxes and valve chambers.

• Verification the tightness of the valves and the network.

• GPS location.

• Detailed computerized report including intervention priorities, thematic plans and register with intervention history.

• Free asset viewer with graphical interface.

• Lubrication with non-toxic penetrating oil (optional).

• Computer assisted hydraulic handling (optional).

Unidirectional rinsing

• Preparation and execution of the flushing roads.

• Flowtime calculated for water saving.

• Reading of NTUs with turbidimeter (optional).

• Verification of the flow obtained and compared to the flow required.

• Modification of flushing routes according to field conditions.

Full report including thematic plans

Restoration of fire hydrants

• Repair without excavation.

• Experienced technicians.

• Lubrication of parts with food grade grease.

• Extensive parts inventory.

• Solar-powered mobile intervention unit.